Technology

In-house developed technology

Since 2005, we have been developing and implementing new technologies in the field of down and feather processing,

allowing our products to reach the highest quality and reduce environmental aspects to the lowest standards.

HUAYE Pre-Sorting

Traditionally, feathers are pre-washed or washed and then dried before being sorted. Huaye’s revolutionary innovation first removes the large feathers, then we just wash and dry the remaining valuable feathers and down. Through this process, we can reduce water consumption by 50% while also reducing down production losses.

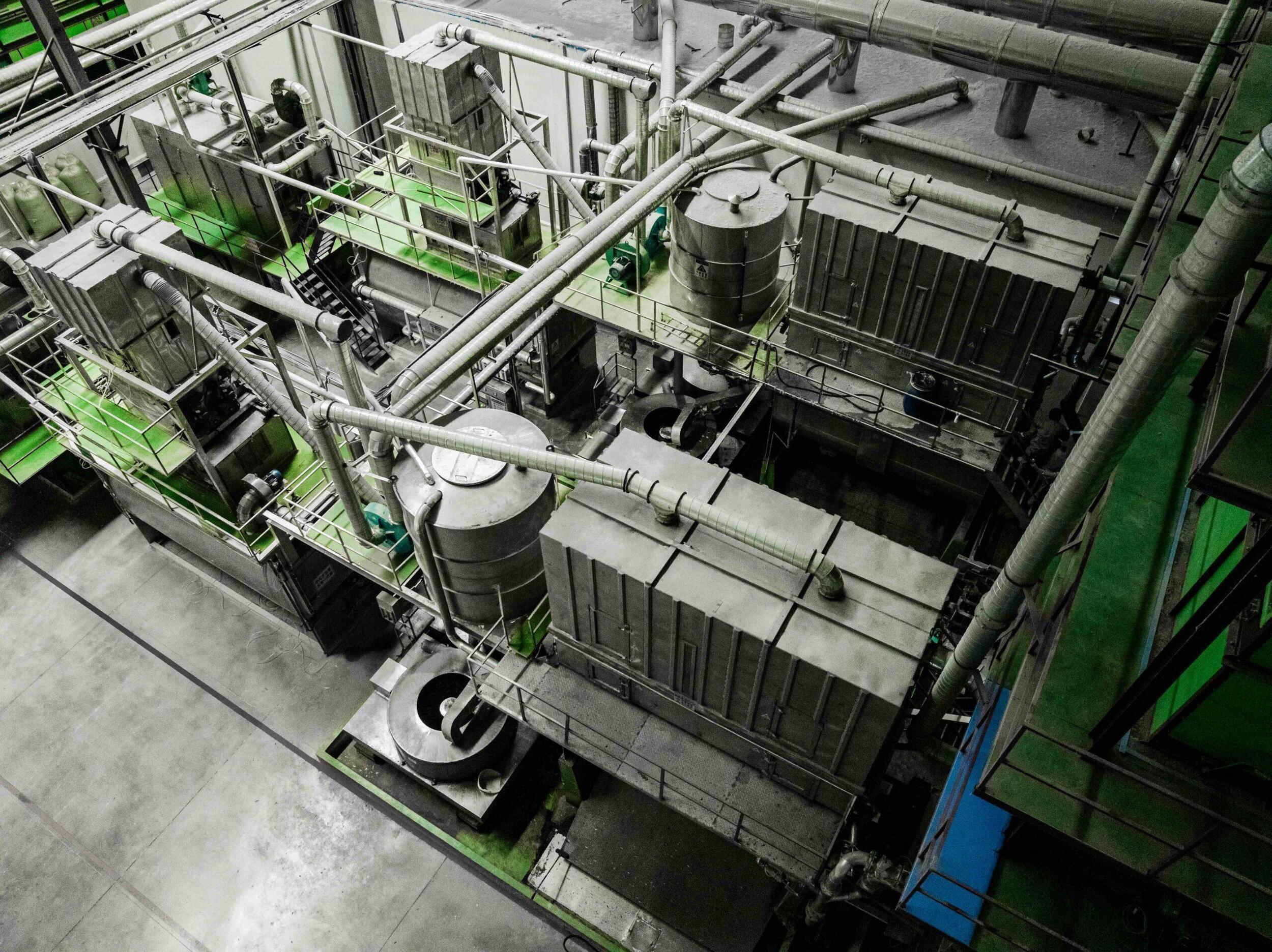

MBR sewage treatment circulation system

The daily sewage treatment water can reach 10,000 tons. The water quality is stable, more than 80% more than the traditional treatment process, this green production method not only reduces the impact on the environment, reduces the consumption of water resources, but also improves the cleanliness of down feathers.

The water washing process of the automatic line is as follows:

1. Firstly, perform pre-sand removal, which means clearing the internal dust before entering the washing tank to reduce water usage and improve washing efficiency.

2. Next, perform fixed-weight feeding, selecting the appropriate washing program based on different product specifications, including water usage, washing frequency, etc., to save water and enhance efficiency.

3. Automatic timed centrifugal dehydration.

4. Automatic timed and quantified drying.

5. Automatic timed and quantified cooling and dust removal.

6. Finally, automatic quantified packaging is carried out.